An alternative concept of "Powder lunar fuel base" giveseconomic justification for the use of resources of the moon for thesatellite constellation.

Production on the Moon from the ground powder, used to fuellong-term orbital tugs with plasma engines and raw materials for the aerospace industry can be an alternative direction ofcolonization of the moon and space exploration. This new line ofcommercial lunar project, realized in practice and is available at cost, with high investment attractiveness, and allows to startcommercial development of space.

The moon is closest to the earth planet in the solar system, it is in close proximity to the ground and within reach of the orbital transport current generation.

Because of its position, the moon is the right candidate to create the first Alien base. Adopted plans for the moon, include the development of her scientific base, with a gradual transition to commercial use. Because of the high cost of a lunar base projects are constantly delayed. But if the first base on the moon at once to create the basis for the commercial operation, it will automatically solve the problem of funding, and attract investors to the moon.

Commercial lunar base, in fact would be the first extraterrestrial colony, by launching further colonization of space. But in order to build a foundation was economically feasible, the base should produce what is useful and marketable product, the benefits of which would have exceeded the cost of its creation and operation.

Of the currently known variants of commercial use of lunar resources are the following:

Production on the moon metal and ceramics for use in orbit, or export to the ground. The production itself is expensive and requires infrastructure, while at the same time it does not give much benefit, and do not currently have a wide demand. Option with the production of products from lunar resources can be a key to the future, when will the development of space transportation infrastructure. In the short term it may serve an auxiliary function, but can not claim to be the main one. Too costly, too low efficiency.

Mining the moon expensive and rare items for export to the ground. In the lunar soil elevated some expensive items such as precious metals and radioactive materials, mainly isotope - "Gelli - 3". The advantages of this direction that solved the problem of transportation costs, due to removal of expensive raw materials, which will be profitable even with traditional transport missiles.The disadvantages of the need for special infrastructure on the moon for the extraction and enrichment of trace elements, due to the extremely high investment. Besides, now there is no workable fusion reactors, and reactors can consume Gelli - 3 will not be for at least another few decades. Commercial production on the moon, trace elements is possible only in the long term. In the near future for this scenario is not suitable technologies and costs are too high.

Production on the moon rocket fuel. It is quite a realistic scenario, especially considering that the fuel in space, the hottest and most consumed consumables. Most of the orbital payload falls on fuel, but the cost of removal from the ground, 5, 10, of thousands of dollars per kilogram of payload output is so large that the production of fuels from lunar raw materials may be commercially viable. In contrast to land on the moon has no atmosphere and low gravity, which greatly simplifies the task of payload into orbit from the moon's surface. In the presence of sources of chemical fuel on the moon, the cost of removal from the moon ten times less than from the ground. And instead of using a jet engine or a powerful catapult, which is quite low orbital velocity allows for the moon, the cost of removal may be reduced to junk. Production of fuel, so do not require large infrastructure costs, as opposed to extraction of trace elements for the production of fuel processing does not need large amounts of soil and low productive operations of enrichment.

Production of fuel on the moon, can certainly be cost-effective solution, but it must be specific to the lunar resource base. On the moon rocks are widespread, but little water and light elements in general. Therefore, the simplest of the known variants, the production of liquid oxygen. Oxygen may be obtained from almost any lunar rock, the method of deoxidation at high temperature.But a lack of oxygen include the fact that it can serve only the oxidizing component of a chemical fuel, in order to get the combustion reaction with oxygen is necessary to have more and fuel.

When oxygen is used mainly as a component of chemical fuel, the problem can be solved by supplying the fuel from the ground of liquid hydrogen. Hydrogen is very light gas, the relative mass of hydrogen combustion in conjunction with oxygen about 12%. The ease of hydrogen allows you to display it on the ground at relatively low cost, since most of the fuel vapors will have a cost-effective lunar oxygen. The disadvantages of this approach include the need for constant supply of fuel from the earth and the bad performance of hydrogen, it is very low-boiling and evaporates quickly.

Recent studies of the moon, give us hope that the moon may be water, in the form of cometary ice in large enough quantities and concentrations of industrial production. Expanding the water into hydrogen and oxygen can get a pair of chemical fuel on the moon, allowing for the lunar orbital fuel, regardless of the supply from the ground. The disadvantage of this trend is that the moon may be too few fields of ice, or its contents in the soil is too low.Now there are not enough details to say something definite about the number of sources of ice on the moon, and their suitability for production.

Another common shortcoming of the concept of chemical fuel on the moon, is its low efficiency. Most of the fuel produced, will be spent on transportation of fuel to the places of consumption. In general, the efficiency of chemical fuels is low, and significantly increase its impossible. That severely limits his ability.

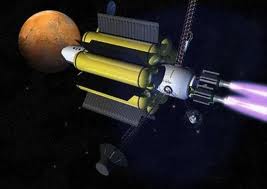

Because of the low potential chemical engines, in all likelihood, they are the next generation of space vehicles will be replaced by more economical "Electro jet" engines that use no energy combustion, and energy of electric current, obtained from solar or nuclear generators. Electric jet engines, on-orbit will be dominant.But chemical engines remain as engine control and auxiliary power units. The most likely type of electric jet engines of the future - "Plasma Engines," as with respect to all characteristics they most versatile and easy to use.

In the transition constellation to plasma engines, fuel demand would still remain. Plasma engines are more economical, but they also need to be spent by the fuel. Unlike chemical engines, plasma, fuel does not burn, and turns into a plasma by electric power supplied from outside. Therefore, Plasma fuel engines is the "working body", not acting as a fuel. Fuel plasma thrusters should not burn, so they can consume as a traditional fuel, and other substances, such as pure oxygen, which does not burn, but may serve as the working fluid.

The advantage of reusable orbital tugs with plasma engines for space, that they frequently reduce the cost of orbital transport, which makes the space more accessible. Including reduced cost and delivery of cargo to the moon, which simplifies the task of industrialization of the moon.

Base on the Moon can provide cheap fuel reusable transport ships with plasma engines, whose creation is expected in the future. As such, the lunar fuel industry does not need the fuel components, or require a lesser degree. Since the chemical and auxiliary engines will be the total fuel consumption will be small.Freed from the need to produce combustible components, the fuel industry in the moon may consume readily available sources of raw materials, lunar rocks, suitable for the production of oxygen.

Production of oxygen on the moon, for the orbital tugs with plasma engines, the best known in the present scenarios of commercial activity on the moon.

Based on the features and capabilities of the plasma engine optimization of production logistics links, I suggest a new approach to the development of lunar resources. Raw lunar base, producing the fine powder of the lunar soil.

Powder from the lunar soil can be consumed by plasma engines with modified fuel system. It can also serve as feedstock for the production of oxygen, ceramics, metals, and products from these materials, space manufacturing facilities in Earth orbit.

In plasma engines the working fluid is heated by electric current, in the form of the electron beam of high frequency or microwave radiation. Plasma isolated from the walls of the motor magnetic field and not in contact with internal engine parts, and therefore can not cause corrosion or deposits of refractory slag.

Features of plasma engines make their unpretentious in choosing the working fluid, they can consume any substance, organic fuel, water, pure oxygen or other oxidants. So they are unpretentious to aggregate state of the fuel, the working fluid can be gas, liquid, or solid fuel in the form of fine powder. The ability of plasma engines consume fuel powder is determined only by the capabilities of fuel system. Create a fuel supply system designed for powder, it is technically not a difficult task, so it is possible to create multi-fuel engines that consume a mineral powder, and the main available on orbit fuel such as liquid oxygen, the organic fuel. Orbital tugs with such engines can run on any available working fluid, but the main fuel for them to be "mineral dust" from the lunar soil, as it is cheaper and available in large quantities.

Mineral dust, must be supplied with fuel lunar base. The main advantages of "Dust fuel base" may include, for its low cost and widespread availability of easily accessible resources.Equipment dusty base as reliable in operation and almost no need to provide the land.

Production of mineral dust, as opposed to liquid fuel, requires no heat or chemical processing of raw materials. You only need to output, mechanical grinding and orbit insertion, so powdered fuel base will have a relatively low weight and high performance.Accordingly, such a project would be relatively inexpensive and have high economic efficiency.

Derivation of mineral powder into orbit, according to my project, it is assumed by a powerful mechanical catapult - "Moonlight sling." Sling is a rotor with ribbons made of Kevlar, a width of about three feet long and several kilometers. On the tape must move carts - conveyors, containers containing lunar material, the containers are discharged from the end of the tape at a certain time, leaving the lunar orbit due to the speed at the ends of the belt 1800, 2000, meters per second.

After launching into orbit containers are collected by special rolling interception and stored on a lunar space station, before the arrival of the next orbital tug.

Orbit insertion using a mechanical catapult uses absolutely no fuel costs, and therefore has a low cost. The very moon sling, a relatively simple and lightweight, compared with possible analogues, such as electromagnetic guns or orbital rope system.Although we can not rule out a future transition to the cable lift, an analog of a space elevator, with a base located at the Lagrange point L - 1, where the attraction of the earth and moon cancel each other out.

Containers for the lunar dust must be disposable, made from mineral fiber, produced in situ from the lunar soil. After launching into orbit, material containers can also be crushed into fine powder, or used for other purposes, as does the production of various designs or pottery.

Moon dust is to be used primarily as fuel for reusable orbital tugs. But it can also be used as feedstock for the production of ceramics, metals, and liquid oxygen. Conduct deep processing of lunar materials, thermal and chemical, is more advantageous in low earth orbit stations than on the moon. Place equipment for deep processing of low-Earth orbit, more profitable, because of minimal transportation costs, natural protection from cosmic radiation and the presence of manned space stations that serve the basis for allocation of production equipment.

Lunar materials, will be much cheaper than the materials delivered to the ground, which makes its use economically feasible. Of mineral dust in orbit can get oxygen, which serves an oxidizer for chemical engines, ceramic products, which can serve as housings for habitable modules and elements of the supporting structures of the metals can be prepared a variety of parts and products that can be widely used. The ability to produce products from lunar raw materials, reduce the need to secure the land for the constellation. That will save money for its expansion and will provide a basis for further development of industrial activities in space.

The proposed concept fuel powder lunar base is unparalleled in the ratio of financial costs and economic efficiency. In addition, it allows you to start using a variety of lunar materials for the constellation. Creating the basis for economically viable production activities on the basis of extraterrestrial resources, which distinguishes it from other variants of fuel bases on the moon.

The concept of the lunar powder fuel base provides an effective business case for the colonization of the Moon and diverse use of lunar resources that can make the next breakthrough in space exploration, with its practical implementation. Relatively low cost and high efficiency make it attractive to investors. Implementation of the concept reduces the cost of orbital transport and opens up new areas for development of space that allows you to count on financial support from the national space agencies and research budgets.

Mineral dust as the primary fuel for orbital engine has several advantages. Production of mineral dust is possible without the high cost of any astronomical objects on the moon, on Phobos, Mars, on asteroids, it is the most accessible and cheapest fuel in the galaxy. With a fleet of orbital tugs consume the available fuel from another planet, humanity can cost-effectively build settlements on the nearby planets and asteroids to develop mineral resources.

Creating a fuel base on the moon and constellation of reusable tugs with plasma thrusters in orbit, can provide a basis for future colonization of space. Resource base on the moon, is the key to the further colonization of the solar system. As such, the lunar base is not just a new direction in space, and a big step toward expansionist movement of humanity into space, the transition of human civilization in space levels.

Nikolay Agapov.